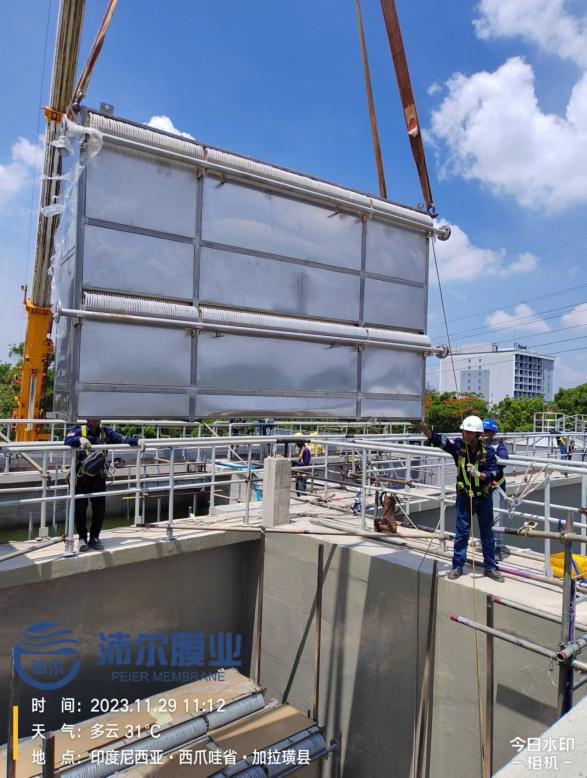

As a company specializing in the field of wastewater treatment, Jiangsu Peier provides efficient and reliable solutions to companies with various wastewater treatment needs at Indonesia’s HM SAMPOERNA Tobacco Wastewater Treatment Station.

Title: HM SAMPOERNA Tobacco Wastewater Treatment Station

Application Technology: Submerged flat sheet membrane MBR technology

Applicant: Jiangsu Peier Membrane Corp., LTD

Affiliated: Jiangsu Peier Membrane Corp., LTD

Recommended Department: Belt and Road Environmental Technology Exchange and Transfer Center (Shenzhen)

Case Area: Indonesia

Firstly, HM SAMPOERNA Tobacco Wastewater Treatment Plant focuses on the efficiency of wastewater treatment.

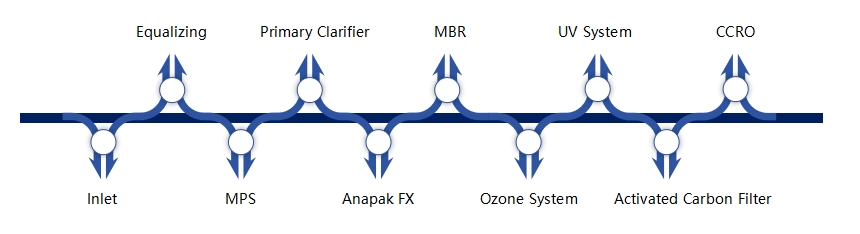

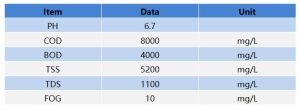

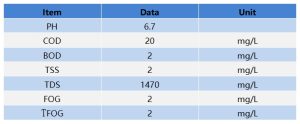

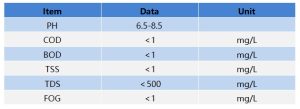

Peier use advanced physical, chemical and biological treatment technologies to effectively remove harmful substances and pollutants from the wastewater, ensuring that it meets national discharge standards. By treating wastewater in a comprehensive manner, Peier can minimise pollution to the environment and protect the health of the surrounding ecosystem.

Secondly, HM SAMPOERNA Tobacco Wastewater Treatment Plant focuses on the reliability of wastewater treatment. 、Peier have a team of experienced professionals who are familiar with the operation of all types of wastewater treatment technologies and equipment. Whether we are dealing with large-scale wastewater treatment or responding to special treatment needs, Peier are able to provide reliable solutions. In addition, Peier regularly maintain and overhaul our wastewater treatment equipment to ensure that it operates properly and to ensure the continuity and stability of wastewater treatment.

Finally, HM SAMPOERNA Tobacco Wastewater Treatment Plant focuses on co-operation with our customers.

Peier are well aware of the uniqueness and special requirements of each company with wastewater treatment needs, so we work closely with our customers during the development of wastewater treatment solutions to fully understand their needs and expectations, and provide personalised solutions according to the actual situation. We always aim for customer satisfaction and endeavour to provide our customers with the best wastewater treatment services.